Processes, machines, equipment, facilities, work areas and offices are designed for success but somehow they malfunction or failed to meet certain standards or expectations. We call these instances as abnormalities. This seminar imparts the organizational system to catch, record and report abnormalities that triggers the development of solutions and revision of standards. It will teach the concept of identifying and classifying process abnormalities as well as the techniques of involving everyone. The benefit to the company will be long term as the Abnormality management System will kick off the evolution of continuous improvement culture. This system is ideal to support Kaizen, 5-S, TPM, Six Sigma and other quality and productivity improvement programs.

Objectives: At the end of this session, the participants will have been able to:

- Understand the proven technique of Abnormality Management System.

- Adopt and emulate the practice and discipline of Abnormality Management.

- Formulate an Abnormality Management System applicable to his/her own company

Agenda:

- Process abnormality and Classification

- The Traditional Non-system View in Solving

- Abnormalities in Manufacturing and Service

- What is an Abnormality Management System

- Features of an Abnormality Management System

- Embarking in an abnormality management program

- Successful Abnormality Management Systems in Industry

- Abnormality Management and the culture of continuous system perfection

Who should attend: Leaders and managers in Manufacturing and Service companies who want to develop a culture of continuous elimination of operational, maintenance, and design related abnormalities.

Language to be used: English

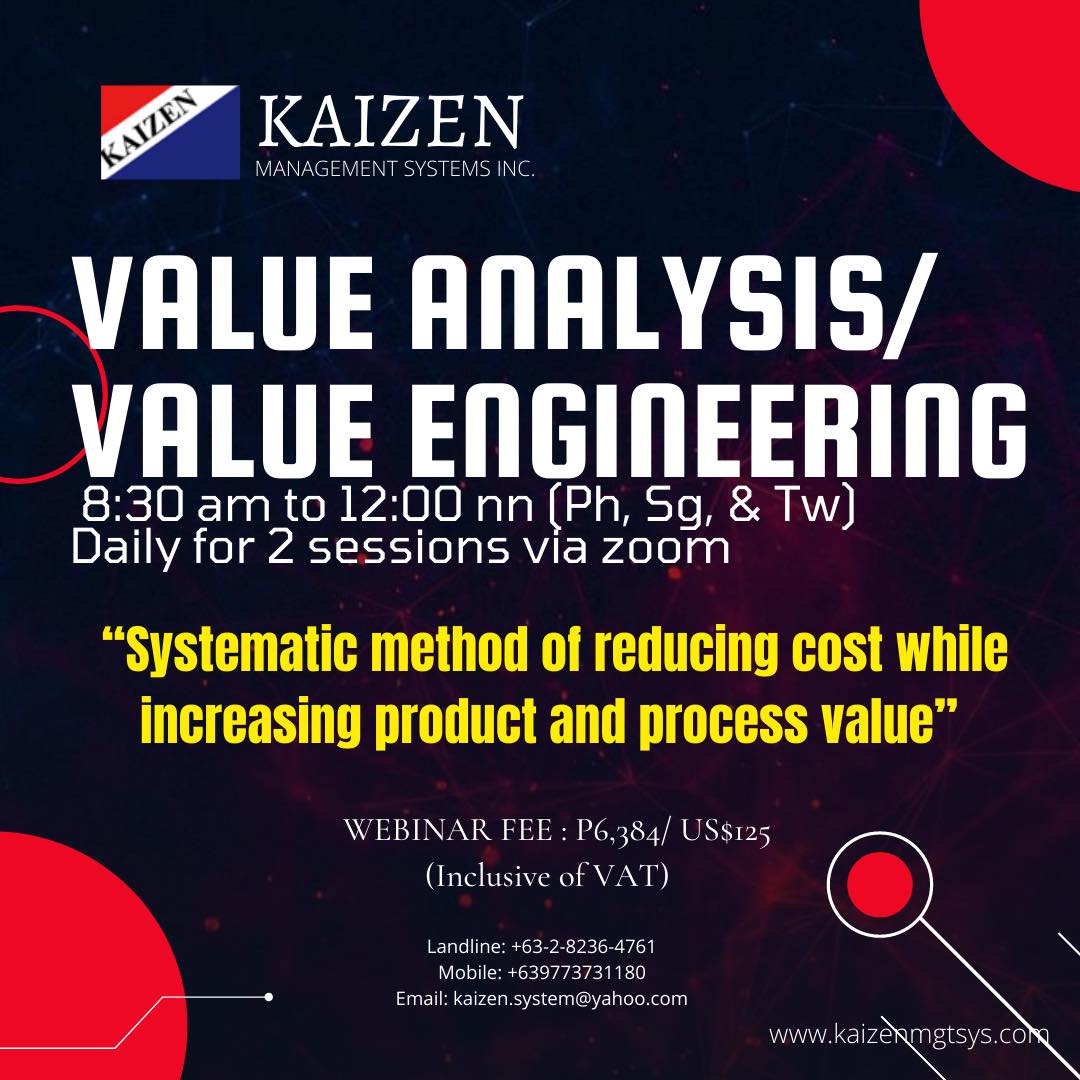

Webinar Fee: P8,736/156USD (Inclusive of VAT) (inclusive of digital pdf copy of the course manuals/workshop & certificate)

Webinar Sessions: 2

Facilitator: Jose S. Villegas

Note: Reservations are confirmed only when the seminar fees have been paid.

Seminar Dates:

TBA – Recommended for face-to-face in-house/exclusive run

(8:30 AM – 12:00 NN daily -Ph,Tw,Sg Time)

“Note: This seminar is also offered in-house or in-plant. Should you be interested contact us at 0977-3731180 | 0927-9233557 | 0969-1020586 or email us at kaizen.system@yahoo.com; jsv@kaizenmgtsys.com”.